Reports by Gard members and clients indicate a significant increase in catfines in both Very Low Sulphur Fuel Oil and High Sulphur Fuel Oil in major bunkering ports during August 2025.

Widespread increase of catfines in marine fuel

Published 09 September 2025

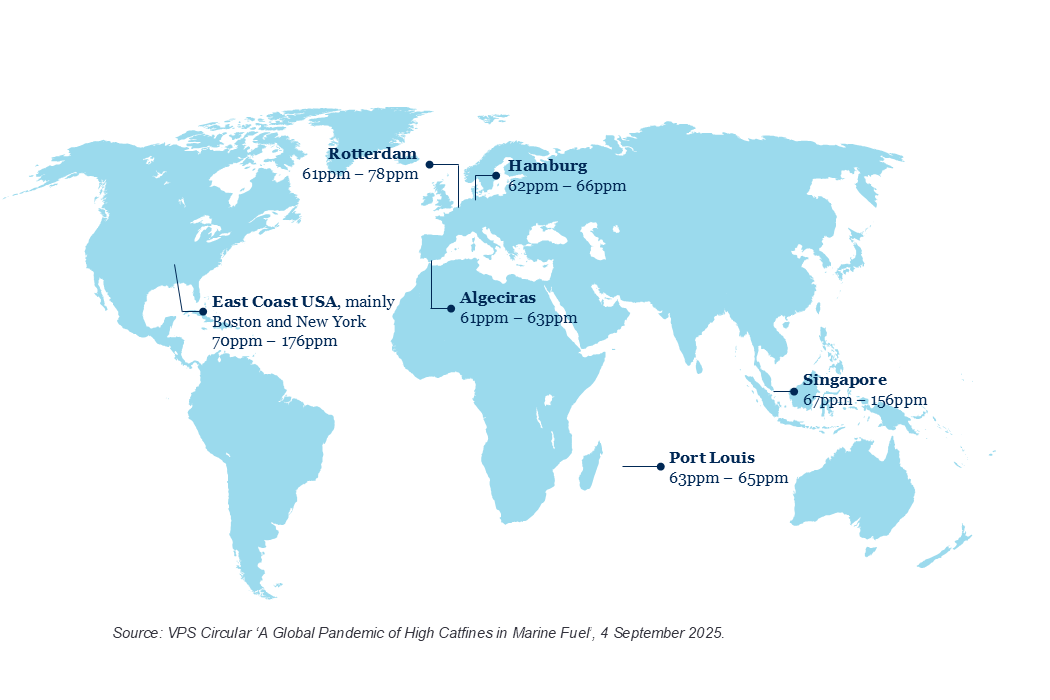

We refer to Veritas Petroleum Services’ (VPS) Circular ‘A Global Pandemic of High Catfines in Marine Fuel’ dated 4 September 2025. Between 11 August and 31 August 2025, VPS observed a high number of elevated catfine levels, ranging from 62-176 ppm, in fuel across the regions shown in the below illustration. This is a trend that mirrors Gard’s own experience.

Understanding catfines

Catfines are microscopic, abrasive particles that pose a significant threat to a vessel's engine. Short for catalytic fines, these particles are composed mainly of aluminum (Al) and silicon (Si). Along with viscosity and water, catfines are considered one of the three most critical properties to monitor in fuel quality at the engine inlet. To put their size into perspective, catfine particles range from 1 to 75 microns. A micron, or micrometer, is just 0.001 millimeters. In comparison, a human hair is about 50 to 70 microns thick, and a fine grain of sand is around 90 microns. Larger particles are more abrasive and can cause severe wear and damage to critical engine components such as cylinder liners, piston rings, and fuel injectors.

Catfines are extremely hard and abrasive. They can scratch or become embedded in the steel surfaces of marine engine components, particularly those that move against each other. When they enter an engine, they can lead to high wear rates and scuffing, resulting in costly damage to key parts. Factors like a vessel's motion in rough seas can stir up previously settled material in fuel tanks.

Catfines in VLSFO

The problem with cat fines is compounded in VLSFO due to several factors. The fuel's typically low viscosity can reduce the effectiveness of centrifugal separators, while its varied composition makes its behaviour unpredictable. If the fuel is not sufficiently heated, waxes can precipitate and clog purifiers and filters, further diminishing their ability to remove these abrasive particles. Adding to the complexity is the risk of re-dissolving cat fines from old tank sediments. Given these challenges, rigorous fuel management is critical.

Industry standards

The ISO 8217 standard sets a maximum limit for catfine levels in fuel. The 2010, 2012, 2017, and 2024 versions set a maximum limit of 60 mg/kg (or 60 ppm) for viscous fuel grades as delivered to the ship. This limit is a significant reduction from the 80 mg/kg limit listed in the 2005 standard. It is crucial to note that the ISO 8217 limit applies to the fuel as it is delivered, not as it enters the engine.

For safe operation, most engine manufacturers recommend that catfine levels at the engine inlet be much lower — ideally below 15 ppm. To meet these requirements, vessels must rely on effective onboard fuel treatment systems. An overview of some of the major OEM requirements for fuel quality before the engine and for fuel cleaning systems can be found in Appendix I of CIMAC Guideline Design and operation of fuel cleaning systems for diesel engines (09, 2024 v2).

Key recommendations

Effective management of cat fines is crucial to prevent engine damage. While most owners and managers have established procedures, we reiterate some of the most important practices to mitigate the risk.

Bunkering & Sampling

Source fuel carefully - Prioritize reputable suppliers when bunkering and avoid less-known local providers.

Define clear specifications - Ensure charter parties include detailed fuel specifications, latest ISO 8217 standard, recommended suppliers, and precise handling and sampling requirements.

Follow standard procedures - Adhere to industry-standard sampling practices, including taking samples from the ship's manifold, using proper cubitainers, and ensuring all documentation (such as the Bunker Delivery Note) is correctly completed.

Analyze before use - Conduct a thorough sample analysis before using the new fuel.

Onboard Storage & Settling

Increase segregation - Maintain increased bunker segregation to avoid contamination.

Test for compatibility - If mixing is unavoidable, conduct compatibility testing and follow specified mixing ratios.

Allow for settling - Ensure the fuel has appropriate settling time in the tanks.

Drain tanks - Settling and service tanks should be drained a minimum of twice daily.

Clean tanks - Clean settling and service tanks whenever possible to remove sediment.

Purification

Choose the right purifier disc based on the fuel's density.

Operate at the correct temperature as recommended by the fuel analysis report.

Consider using both purifiers (in parallel or in series) at appropriate feed rates to increase efficiency.

Maintain purification units with proper care and maintenance.

Monitoring & Prevention

Monitor fuel filters carefully for signs of clogging.

Be aware of sludge formation and filter clogging, particularly after heavy weather.

Conduct regular sample analysis of fuel from before and after the purifier to confirm the unit's efficiency.

Perform periodic cylinder scrape-down analysis to check for abrasive wear.

VPS also recommends taking fuel system check samples to assess the fuel treatment efficiency at the engine inlet or as close to it. This data is critical for any subsequent assessment of increased engine wear.

We would like to thank Veritas Petroleum Services for the above information.