The revision of the International Grain Code was adopted at the IMO Maritime Safety Committee in 2024 and will come into effect on 1 January 2026. The main purpose of the amendment is to formally incorporate into the code the cargo handling method of “specially suitable compartment, partly filled in way of the hatch opening, with ends untrimmed”. This article highlights the key changes and discusses potential practical and legal implications.

Updated 17 December 2025

Published 10 December 2025

The International Code for the Safe Carriage of Grain in Bulk provides specific requirements for the loading conditions according to the following classification:

filled compartments (trimmed)

filled compartments (untrimmed)

partly filled compartments.

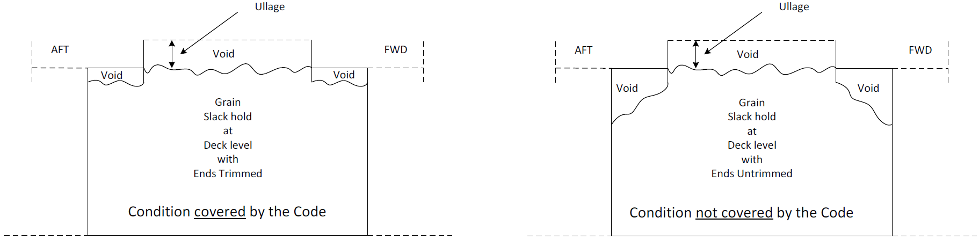

In the practice of loading ships with grain, a loading condition is frequently observed where a compartment is "specially suitable" as defined in A 2.7, filled up to or above the bottom edge of the hatch end beams but not to the highest possible level in way of the hatch opening. The condition where the grain cargo is slacked in the coaming of a "specially suitable compartment" with the ends being trimmed according to A 10.6 is illustrated below to the left. The same condition with the ends untrimmed (illustration to the right) is not covered by the current Code and cannot be calculated for stability purposes in an accurate fashion. This condition often arises unintentionally due to variations in cargo stowage factor, or operational and voyage order constraints.

(Refer: MSC 101/21/12, 5 March 2019)

A ship finishing in the condition shown on the right therefore may formally be not in compliance with the Grain Code, even if adequate stability could be categorically demonstrated by the calculations. To address this, Canada and United States jointly proposed for a new output on amendments to the International Code for the Safe Carriage of Grain in Bulk in 2019 (MSC 101/21/12). These amendments to allow partly filled grain holds with untrimmed ends, were adopted via Resolution MSC.552(108) at the 108th session of the Maritime Safety Committee (MSC) in May 2024 and will come into effect on 1 January 2026.

The changes coming into force as of 1 January 2026

This amendment formally recognises this intermediate loading condition and requires that the Grain Loading Manual include the corresponding heeling moment values for “specially suitable compartment, partly filled in way of the hatch opening, with ends untrimmed”. It refers to “a specially suitable compartment which is not filled to the maximum extent possible in way of the hatch opening but is filled to a level equal with or above the bottom edge of the hatch end beams and has not been trimmed outside the periphery of the hatch opening by the provisions of A 10.4”. In this scenario, the compartment is filled to or above the bottom edge of the hatch end beams, but not to the maximum possible level, and the ends outside the hatch coaming are left untrimmed. The grain outside the hatch opening may rest at its natural angle of repose, and only the free grain surface in way of the hatch opening must be level.

One of the advantages of this method is that it eliminates the need for trimming the ends, which was previously required, thereby significantly reducing cargo handling time. Allowing trimming operations to be omitted beneath a cross deck significantly reduces the operational burden while maintaining compliance with safety requirements, this is presumed to be the rationale behind the amendment. When trimming is deemed unnecessary, the fundamental premise is that the risk of lateral movement does not arise. Nevertheless, safety considerations remain critical, including recalculating the inclination moment, shifting moment, and cargo volume curve under the new configuration, and ensuring that stability calculations (including residual stability) are accurately reflected. Failure to meet these requirements may result in the condition being judged unsafe, creating a risk of warnings during cargo handling authorisation or inspection.

The amendments apply to new buildings with keel laid on or after 1 January 2026, and to existing ships wishing to use the new loading condition for improved flexibility and compliance. For existing ships, the amended Grain Code can also be applied to improve loading flexibility and demonstrate compliance with the new requirements.

Actions required by vessels and owners

While the changes offer the advantage of reducing cargo handling time, if existing vessels are to load in this way it will be necessary to address the heeling moments for the new loading configuration and update the Grain Loading Manual accordingly. The following actions should be taken by shipowners/operators:

Revision of the Grain Loading Manual: Incorporate into the existing manual the new heeling moment curves, filling levels and volume curves, and assumptions regarding the angle of repose.

Update of the Grain Loading Computer: Integrate the new loading configuration into the loading computer and obtain certification.

Class and Authority Approval: Submit the revised Grain Loading Manual (for the relevant vessel) to the flag administration or a recognised organisation for approval. For vessels intending to use the new condition, the definition of “specially suitable compartment” must be correctly included in the manual.

Coordination with Charterers and Loading Ports: Discuss in advance with charterers, grain shippers, and stevedores the potential use of the “new loading condition” for alignment of all stakeholders.

How this matters for P&I claims

As we have seen, the upcoming revision of the Grain Code allows untrimmed ends below the Cross Deck with only the exposed surface near the hatch level. If the revised inclination/shifting moments and residual stability are not correctly calculated and approved, any resulting list or cargo shift may be argued as foreseeable and preventable, which potentially weakens a carrier’s defence under Hague or Hague‑Visby Rules by assisting the cargo interests to argue about the vessel’s unseaworthiness or want of due diligence for seaworthiness at the commencement of the voyage. Stakeholder alignment is critical in that it could prevent or assist carriers combat such arguments.

Potential legal implications

One issue that we see being raised is whether Owners or Charterers should pay for the costs associated with the operational steps above. The cost of revising a vessel’s manual documentation, updating computer software and dealing with Flag administration could be significant, so if the Charterers want this to be done, should the costs be for their account? Unfortunately, the answer is not easy and will depend on the particular terms of the charterparty in question. As there is no obligation on the owners of existing vessels to make any of these changes, the starting position is likely to be that Charterers must persuade Owners to take these steps and revise their manuals – rather than being able to force it on the Owners. This is more likely to happen when negotiating long term time charterparties.

It is also important to note that if a vessel is not certified to load under the new condition, time may be lost due to trimming requirements, or loadings may be cancelled or reduced if shippers cannot or will not trim cargo. Therefore, a vessel’s capabilities and limitations should be communicated early when grain carriage is anticipated, allowing time to address any loading method issues. Parties may wish to include express provisions in the charterparty regarding the vessel’s capabilities and allocate responsibility for any time or costs arising if loading under the new condition is expected.

Sources:

IMO: Amendments to the Grain Code (MSC.552(108), adopted on 23 May 2024)

IMO: The International Code for the Safe Carriage of Grain in Bulk (MSC.23 (59), adopted on 23 May 1991)

IMO: Proposal for a new output on amendments to the (MSC 101/21/12, 5 March 2019)